BacTech Environmental Corporation (CSE: BAC | OTCQB: BCCEF | FSE: 0BT1) is a Canadian cleantech company specializing in the environmentally responsible recovery of valuable metals from difficult and toxic concentrates and mine waste. Using its proprietary bioleaching technology (BACOX), BacTech employs naturally occurring bacteria to oxidize sulphide minerals, safely releasing metals such as gold, silver, copper, cobalt, and nickel while permanently neutralizing harmful elements like arsenic.

For over three two decades, BacTech has championed sustainable mining solutions that convert flotation concentrates and legacy liabilities into new opportunities. Its flagship project, located in Tenguel–Ponce Enriquez, Ecuador, represents the South America’s world’s first commercial bioleach plant designed to treat arsenic-rich concentrates from numerous sources. The facility will operate under a “Build/Own/Operate philosophy—producing no toxic waste and transforming the lives of employees through higher pay and better living conditions.

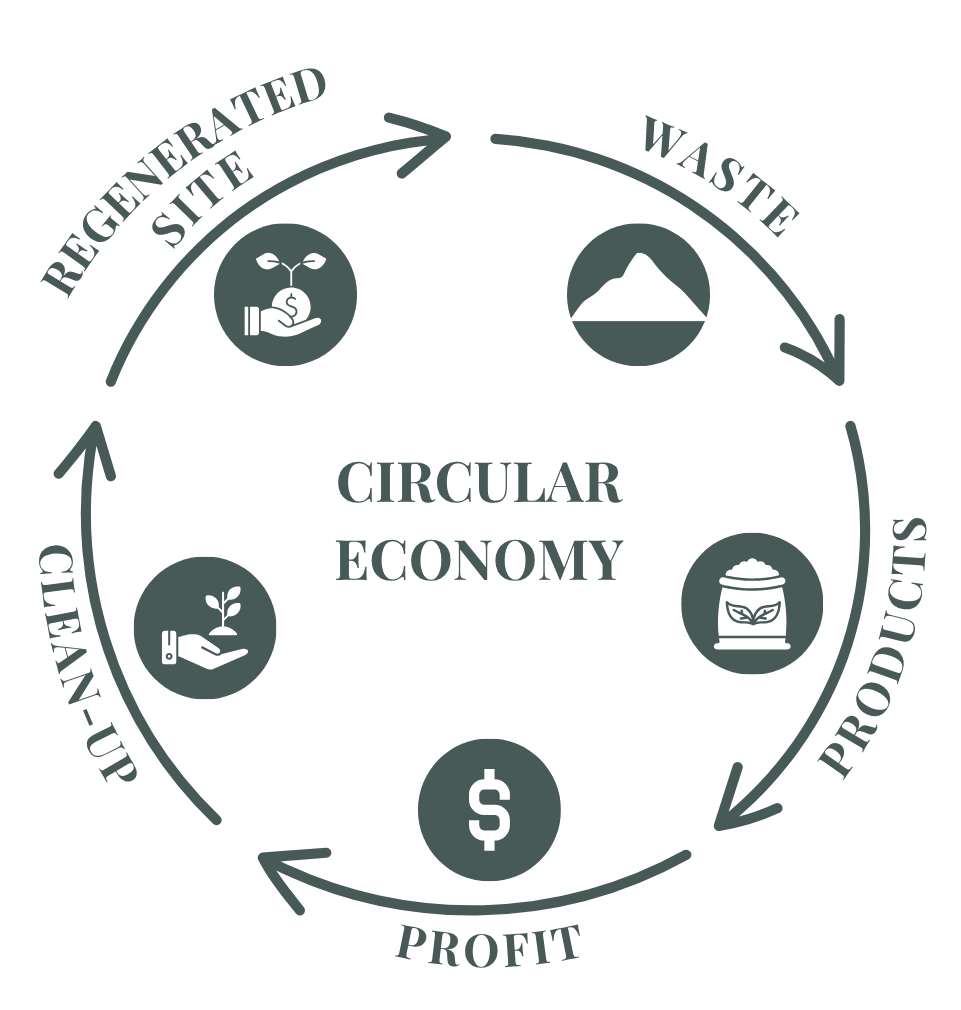

Beyond Ecuador, BacTech is advancing a “Zero-Tailings” nickel recovery initiative in Sudbury, Canada, focused on reclaiming metals from massive pyrrhotite tailings. This patent pending process is designed to recover critical minerals while generating additional revenue streams from iron, fertilizer, and silica products, supporting Canada’s circular-economy and green-steel ambitions.

BacTech’s mission is clear: to prove that environmental stewardship and profitability can coexist. By combining biotechnology, ESG principles, and innovative financing such as Green and Social Bonds, BacTech offers a new model for mining — one that cleans up the past while building a cleaner, more sustainable future for the industry and the communities it serves.

Cleaning up the past. Building a sustainable future.

BacTech Environmental is positioned to deliver strong financial performance through its flagship

Tenguel Project in Ecuador and future expansion initiatives.

Phase 1: Strong Returns from the Tenguel Plant

Tenguel Plant, with a capital cost of approximately US $22M, is designed to process 50 tonnes per day and generate 35,000 ounces of gold annually. At a gold price of US $3,500/oz, this equates to over US $120 M in annual revenue with an after-tax payback period of just one year.

Phase 2: Scalable Growth and Expanded Output

The subsequent Phase 2 expansion will increase capacity to 250 tonnes per day, scaling production to over 100,000 ounces annually. With a combined CAPEX of US $80 M, projected revenues exceed US $350 M, supported by low operating costs (~ US $212 per tonne) and strong EBITDA margins.

Economic Strength and Risk Mitigation

Economic studies highlight a Net Present Value (NPV) exceeding US $100 M for Phase 1 under conservative assumptions, with substantial upside at higher commodity prices. BacTech has also secured a Government of Ecuador Investment Protection Agreement, guaranteeing international mediation, tax stability, property rights, and 12 years of income tax exemption.

Beyond Ecuador: The Zero Tailings Waste Initiative

BacTech’s Zero Tailings Waste Initiative provides additional upside through the monetization of metals and by-products from legacy mine waste — creating new revenue streams across iron, fertilizers, and base metals while advancing circular-economy goals.

LEADING THE FUTURE OF SUSTAINABLE METAL RECOVERY