FROM WASTE TO BREAKTHROUGH

Our pilot plant in partnership with MIRARCO is paving the way for large-scale commercialization of sustainable mining solutions.

CANADA’S CRITICAL MINERALS ADVANTAGE

Transforming pyrrhotite tailings into a $15B opportunity through clean, zero-carbon bioleaching.

Canada is a leading producer of critical minerals and is increasingly focused on sustainable extraction to support low-carbon technologies. The Greater Sudbury Basin in Ontario offers a significant opportunity, containing 75–100 million tonnes of pyrrhotite tailings, with an estimated value of US$15 billion in Nickel alone. Historically treated as waste, these tailings present both economic potential and an environmental challenge.

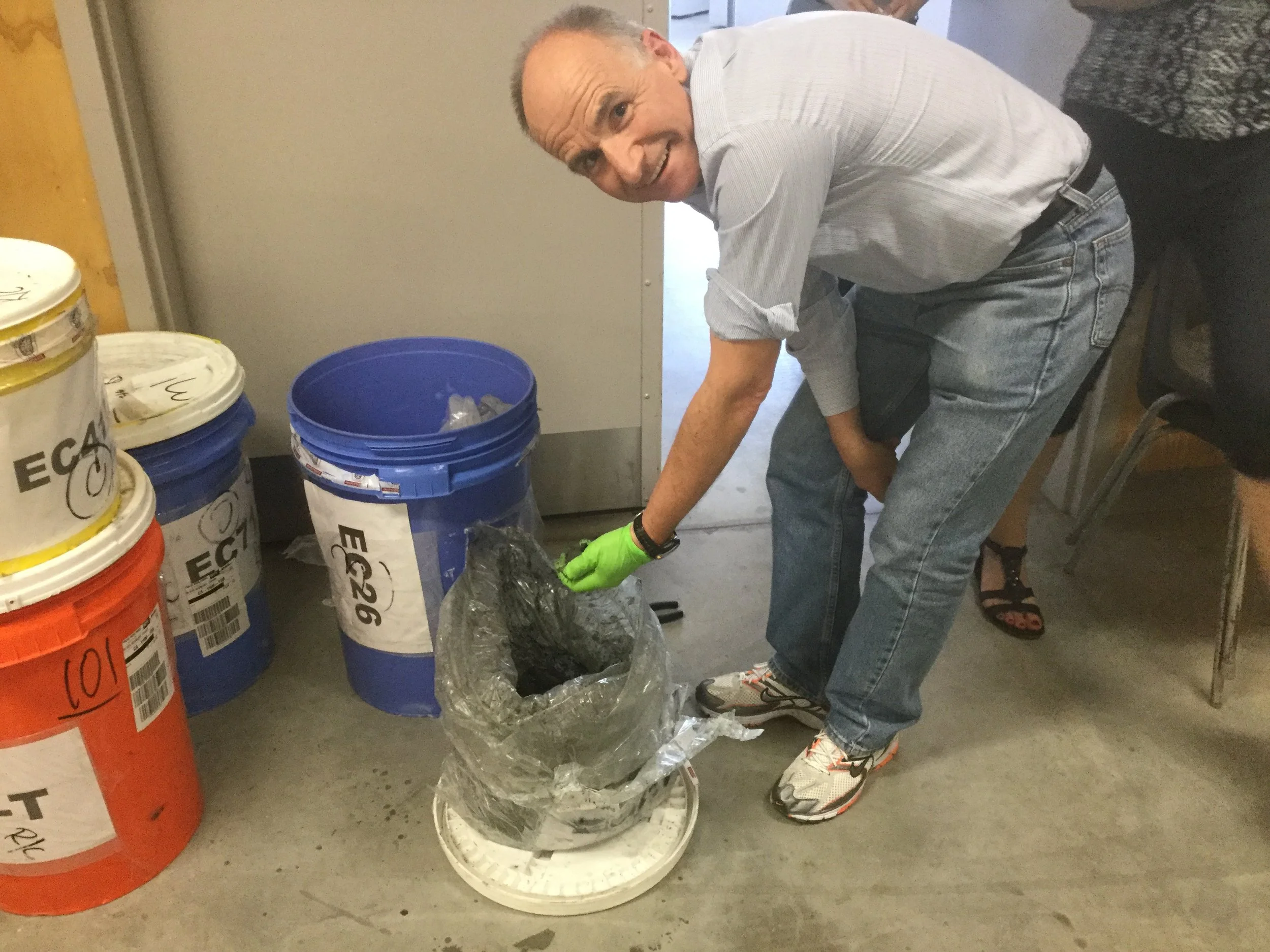

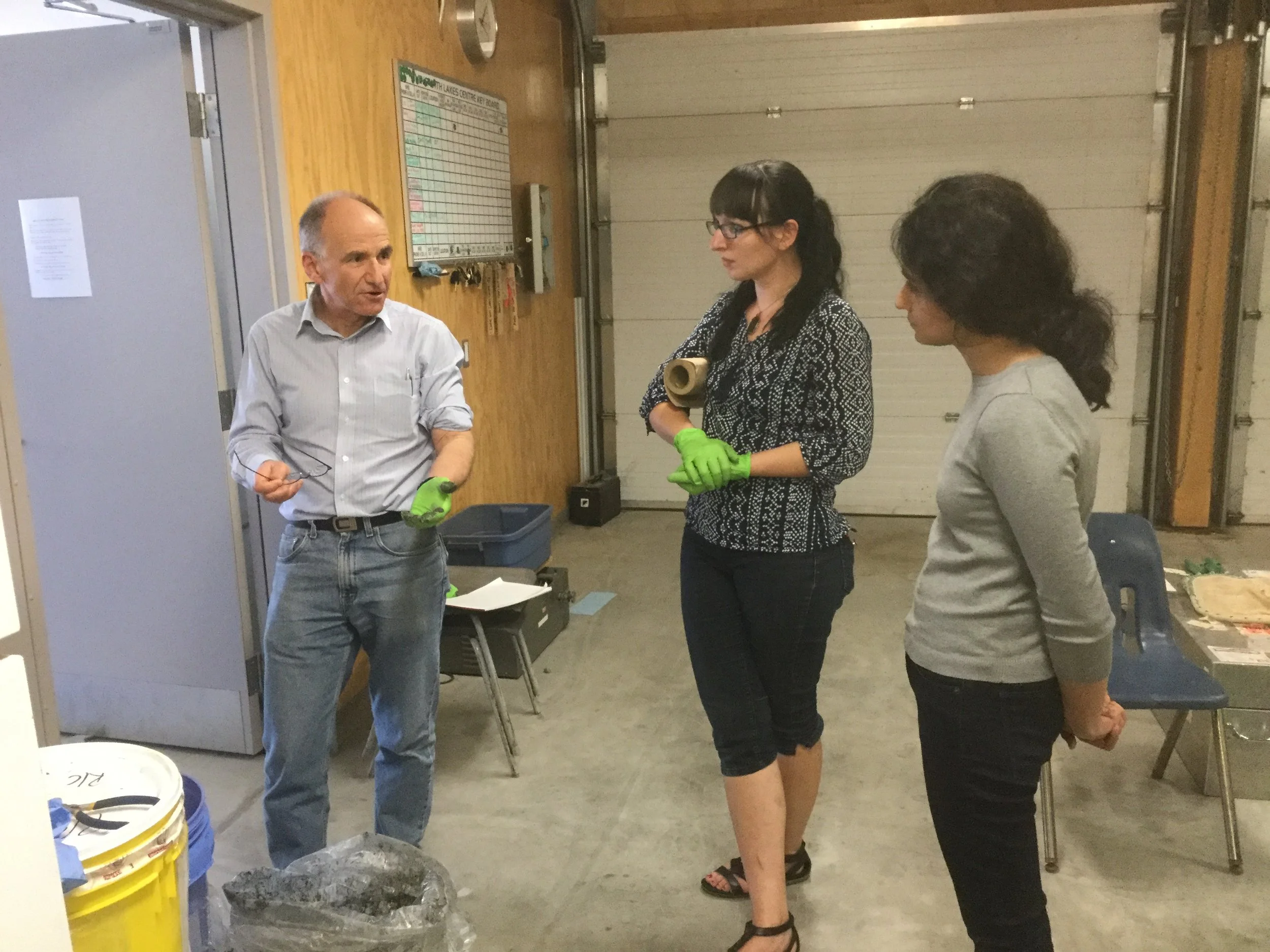

BacTech is applying its patent-pending 0 Tailings technology to recover Nickel, Copper, Cobalt, Sulphur, and Green Iron while minimizing environmental impact through a zero-carbon process. A pilot plant in Sudbury, developed in partnership with MIRARCO, is testing continuous bioleach processes to generate design data for full-scale commercialization.

This initiative aligns with Canadian government priorities, including funding programs supporting sustainable mineral production, and addresses rising global demand for EV battery metals and green steel. BacTech’s project demonstrates how responsible innovation can unlock economic value while advancing environmental and social outcomes.

Pipeline & Updates

A pilot facility has been built in Sudbury by Dr. Nadia Mykytczuk (MIRARCO) to validate the process and optimize recoveries. The next step: securing financing for a commercial-scale demonstration bioleach plant to support Canada’s sustainable supply of critical metals and green steel inputs.

-

Developed a patent-pending pyrrhotite bioleaching process for Nickel, Cobalt, Sulphur, and Green Iron recovery.

BacTech is leveraging its proprietary bioleaching technology to convert historic tailings in the Greater Sudbury Basin into valuable resources while minimizing environmental impact. This phase established the scientific and technical foundation for pilot-scale operations, including early process simulations and design parameters.

-

Validate the bioleaching process and generate design data for commercialization.

A pilot bioleach facility has been constructed in Sudbury in collaboration with Dr. Nadia Mykytczuk of MIRARCO. The plant tests continuous bioleach operations, optimizing recovery rates and refining process parameters. Insights gained here will inform the development of a fully integrated demonstration plant.

-

Transition from pilot to full-scale production.

The next major milestone is securing financing for a commercial-scale bioleach facility. Following funding approval, BacTech will advance to construction and commissioning. The commercial-scale plant will unlock substantial economic value, create local employment, and support Canada’s sustainable supply of critical battery metals and green steel inputs.

Upon completion of financing, BacTech will initiate plant construction and commissioning activities. The facility will serve as a sustainable solution for processing high-arsenic gold concentrates locally, reducing environmental risks and enabling equitable compensation for regional miners. This phase marks the transition from planning to execution, positioning the Tenguel project to deliver meaningful economic, social, and environmental benefits to Ecuador.

Driving Canada’s Clean Mining Future